Some Countermarche Nitty-Gritty: Size, Sheds, and Texsolv

June 15, 2008

I received some interesting responses when I posted about my problems winding warps with a warping mill and beaming them on. Jane, solo warper and owner of international looms, had raddle advice: slit paper towel tubes. And I was all like, duh! and yet, wow! One of the things I love about weaving is the way household objects start becoming weaving tools; Jane uses Home Depot painter’s paper to separate her warp. Cally offered hope of a well-trained husband. Katherine, a sectional warper, likewise recommends skilled beaming help. A bit later I found out Charleen has a vertical reel that works fine for her, now that she has learned to overcome her dizziness (though she does wind in quite small bouts). Dizziness is one thing that has never been a problem for me while warping! I wonder if this is a hidden advantage of the horizontal reels. The lengths of warp slide past your eyes up-and-down, rather than side-to-side like scenery whizzing past a moving car.

I also got an out-of-the-blue comment from a seasoned Bergman Loom owner. One of my hopes for this blog has been that new Bergman owners will find it and be spared some of the trouble I had with mine in the beginning, but I was surprised to hear from a veteran.

The lady was kind enough enough to measure her loom and send pictures. I asked her to do this because I have long suspected that my incurably narrow sheds are due to my loom being shorter in the castle and/or breast beam than later Bergman looms. There are not many pictures of Bergman looms on the internet–none full-figure–but I do have an magazine article from the 1940’s with a grainy photo of half a dozen set up in a library meeting room for a guild exposition. It was very hard to see, but I pored over it, and it seemed to me the castles were taller than mine.

This lady’s loom was made in the 1970’s, shortly before the Bergmans closed up shop. Her castle and breast beam are nearly the same height as mine (in fact my breast beam is 1/2 inch taller), but my upper and lower lamms are set 2” closer together.

Bingo! When the upper and lower banks of lamms on a countermarche are attached to the loom too close together, your sheds are small. Why? Well, when you push on the treadle, the rising lower lamms and the falling upper lamms quickly crash into each other. At that point, you can’t push the treadle any farther, so that’s as big as your shed gets. Ditto the sinking shafts and the rising upper lamms: crash! The best you can do is to adjust the cord lengths for all the moving parts for maximum non-crashing movement.

This is why Glimåkra looms are so hugely tall (aside from needing somewhere to hang the beater). The more vertical space in which your shafts and lamms and treadles have free play, the bigger your sheds can be.

. . . as I understand it after crawling around my loom for months, trying to maximize my sheds. Not that I have ever woven on a full size Scandinavian countermarche. I’ve just thought a whole lot about loom design. There is no better education in simple mechanics than pinpointing the shortcomings of your own machine.

The Bergman loom was designed low and compact in order to be quite strong, yet fold easily when warped. This has wonderful advantages. You don’t have to take it apart to get it through a doorway, just fold in the wings. But there are sacrifices you will make with a smaller loom. If the height of your countermarche loom affects the size of your sheds, the depth of the loom affects their quality. A Bergman loom may be decently deep for a countermarche, but not for a Scandinavian-style countermarche.

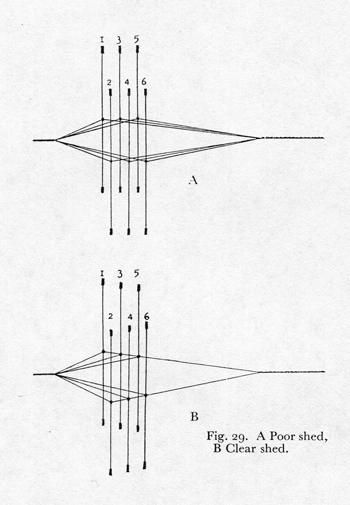

Deeper looms allow for more inches of stretched warp from back beam to breast beam. This means (how do I describe this; it’s all so visual!) more total elasticity, therefore less stress on your threads while weaving. For instance, pull on an 80” inch piece of string, then a 20” piece of string: there is more “give” in the 80” piece. Now picture each of these two pieces of string stretched across a brick and tacked to the floor at both ends. The 80” inch string approaches the floor from the top of the brick at a gently inclined angle, whereas the 20” string is very sharply inclined. On a short looms the sharp incline of the warp from the lowered shafts to the fell line contributes to bad sheds. This is because the thread angle produced by each separate lowered shaft will be quite different from its neighbor’s. The steep angle magnifies all the discrepancies. Your shuttle will try to sneak under the high threads when it’s supposed to glide over them. Here’s an old picture I borrowed for a good cause. Thank you, Ulla Cyrus.

You can get good sheds with a Bergman (I’m taking this on good faith from Mrs. S-G), but it will take a lot of fiddling.

My Texsolv tie-up is a problem in this department. A person can only fiddle with Texsolv so much, because it only allows adjustments in 1 cm increments. I would really appreciate being able make finer adjustments than that. I decided to make a fresh start with the Texsolv because my loom’s tie-up had been Frankensteined. The cords it came with were ancient, all lengths, several thicknesses–none of which fit through the holes in the lamms. I wrapped the ends with masking tape and worried them through for my first warp, but it was hellish. The rest of the cords were clearly on their last legs, er, strands. The heddles were so many sizes, I couldn’t even guess which size was correct. I think someone had simply grabbed a bunch of assorted heddles and cords belonging to various looms from what remained of Mrs. S-G’s weaving school supplies.

You wouldn’t think so, but restringing the loom with Texsolv was a huge job, as well as expensive. My advice? If you don’t have to go the Texolv route, don’t–at least not until you have woven 3 or 4 warps. Unfortunately Bergmans take less kindly to Texsolv cords than most looms. As well as the difficulty making fine adjustments, the usual benefits of Texsolv aren’t available to Bergman owners. Because there are only 6 holes in the treadles of an 8-shaft Bergman loom, you must must make old-fashioned treadle loops. This means no going-through-the-treadle-hole-anchoring-underneath. No cool Vävstuga knitting needle tie-up. Just a messy loop-through-a-loop secured with an arrow peg.

Another inconvenience: the holes in Bergman lamms are small. Unless you take a drill to them (Please don’t!), it will be a real pain to get a Texsolv cord through. You will spend a lot of time with a candle, melting and shaping the ends of all 80 tie up cords to severe 1” points.

That said, my Texsolv tie-up is a big improvement over the one my loom came with. I even replaced the wires that went from the inner jacks to the lower lamms. None of the several lengths of wire that came with the loom were the right length–more Frankensteining. Since Texsolv is slippery, this seems to work okay, although it adds a little bulk between the shafts.

If I had it to do over again I might look harder for some linen tie-up cord. Did you know dense, non-stretchy cord is really hard to find? Some sources I consulted recommended linen drapery cord–the kind that goes around the pulleys on fancy fitted drapes, or that you use to string roman blinds. In the 21st century? Pff, doesn’t exist for normal mortals! Though I suppose a person could try asking a seamstress or an upholsterer who sews custom drapes. Pretty much all non-stretchy cord is synthetic now, and you really need the friction of a natural-fiber cord to make the treadle tie-up knots and Bergman twist-around-a-cuphook adjustments hold properly. I recently discovered that Earth Guild carries seine twine.** I bought some and it is very sturdy but not thick enough enough for the treadle tie-up. I wonder if there are any linen carpet warps heavy enough and highly twisted enough to work for that?

I would still buy Texsolv heddles, though. The string heddles were a pleasure to thread, and easier on my eyes than shiny Texsolv, but really needed to be replaced. Personally, I knew I was not going to make a heddle block and tie 900 new string heddles, so Texsolv was just dandy!

Let me wind up with a testament to the power of the Internet. While I was composing this I heard from a brand new weaver who just yesterday bought a lovely older Bergman like mine. It’s really exhilarating to have something to offer! I had been wondering if there is any point in talking countermarche shop at such length (Like dreams, eccentric looms are always most interesting to their owners.), but now I think I will go ahead make this the first in a series of related posts, with excursions back to my current project and whatnot. A sort of Rough Guide to Bergman Weaverland. Maybe it will even entertain some armchair travelers.

**Sorry, I meant to say Earth Guild carries hawser twine. “Seine twine” was stuck in my head because the old books say to use linen seine twine for heddles. It seems to be a marine product. I see Camilla Valley Farm sells it in cotton and cotton/poly for tapestry and rug warps. It looks a little lighter-weight than my hawser twine.

June 16, 2008 at 2:31 am

I have a locally made countermarche loom currently in pieces because my weaving guru us otherwise occupied. I found your post exceedingly interesting. I have Texsolv tie-ups but string heddles. There was extra cord (linen I think) and my weaving friend (who took the loom apart for moving) worned me to hang on to the cord since it was expensive and hard to get. I will now give the string heddles a try having read your experience.

June 16, 2008 at 10:02 am

Do it! Do it! Americans really need this education. And a whole lot of American weavers don’t even know anything about a counterbalance loom either.

June 16, 2008 at 10:53 am

Thanks for the encouragement, Peg.

Glad to to be useful, Swanknitter.

June 17, 2008 at 7:26 am

Great post, with lots of in-depth information. Thank you for the help! I’m so lucky that you’re ahead of me on all of this!

June 17, 2008 at 7:28 am

Oh, I forgot to mention — as a spinner, it’s probably not too difficult to spin linen cord, although flax is something I haven’t had a chance to try yet.

June 18, 2008 at 9:24 am

What a great notion! When I think of spinning I think of making thread or yarn, not cord. I have sort of made up my mind to go with commercial yarn, and not “be” a spinner, because I know how time-consuming spinning is. I am a very slow weaver, and it already feels as if I don’t have have enough years left in my life to do all the weaving I want to do. But I have to admit, I LOVE spinning wheels (beautiful wooden machinery! my favorite thing!) and am strangely attracted to the idea of growing and processing flax after reading Edward F. Worst’s very old book on the subject. I think it was called “How To Weave Linens.” (Yeah, I know, retting and hackling; talk about time-consuming!) Linen is my favorite kind of cloth, and there is not a great variety of linen thread available. What I’ve seen is VERY expensive. You have to get a special wheel for it, don’t you?

June 18, 2008 at 9:25 am

Really nice post and very thorough! I have a full sized countermarche made by Woolhouse Tools (www.woolhousetools.com) The owner of the company, John Low is also a texsolv dealer here in western Canada. There is a finer texsolv cord avialable which may be better for adjustments than the ‘regular’ cord. John is also very knowledgeable and may be willing to help answer some of your shed questions being fully familiar with looms and the building of them. He’s been making looms since 1977. If you visit my blog, you will see various entries showing my loom. There are more detailed pictures in Jan 08 archive. John’s web site also shows his looms.

Another thought is if you know a local carpenter, you could have the castle on your loom rebuilt to extend it to the better height. Just provide them with the new measurements and select the woods. It’s a nice way to customize a loom.

Good luck!

Susan

Duncan, BC

June 18, 2008 at 9:25 am

Or attachments, maybe?

June 18, 2008 at 10:10 am

Whoops, that last was an addition to my response to Spinninglizzy, before Susan’s comment appeared. I was referring to the possible existence of spinning wheel attachments for spinning linen.

Thank you for the suggestions, Susan! I visit the Woolhouse tools site to sigh longingly over their looms. I have been telling myself that some time in the indeterminate future (when we have a house) I will invest in a Gertrude for a “big” loom. Now I have learned from your blog that Mr. Low is going to be retiring, I’m afraid of missing my chance! My husband has even suggested going on a vacation to BC to visit their factory, so I can make sure the Gertrude is as wonderful as I suspect, and be seduced into ordering one. (Which we will then have to put on the roof, as there is no other place for it here!)

l investigated different texsolv for the Bergman a while ago, but only found “regular” and two sizes of “heavy duty.” What I have now is the regular cord with the buttonholes every 12mm. Did your loom come with the “heavy duty” kind?

June 20, 2008 at 9:16 am

My loom came with the regular cord with a slot every 1 cm and I would agree that there are times when a finer ajustment would be nice but that’s me being nit picky! There is a finer cord (I have seen it) but I don’t know how the slots are spaced.

With regards to the Gertrude (my loom is named Emmatrude and is number 61) it is a dream to weave on and I have no regrets in ordering one. It’s been 10 years this July since it arrived (that long already??) and even though I have another loom, the Woolhouse is my prefered choice to sit at.

There is a 36″ wide version made now if you seem to weave textiles of that size or less and so it would take up less room and cost less too. If you can afford it, get the 20+ tie up assist. You will not regret that! It takes you out from under the loom and weaving faster when it comes to tie-up’s.

Yes, the Low’s are quietly looking for a buyer for their company but it is their intention to find someone who will carry things on and provide the same equipment and service. The ‘factory’ is a large workshop at their property in Armstrong BC and John does all aspects of the work himself.

Call ahead to ensure they are home. They are really nice people and tell them Susan says hi.

June 23, 2008 at 10:20 am

Really helpful post! I’ve read through it several times, but I think the only way everything will become clearer to me is if I jump right in and start connecting things.

You can buy a spinning wheel that is optimised for spinning things like flax, but you don’t have to. Just about any modern wheel can spin anything. As to attachments, you may have to purchase faster whorls, but again, it’s not absolutely necessary. As to growing flax, I understand you can have a lifetime supply of it for spinning if you grow it in a small 2’x2′ plot. I just can’t start anything new right now. I’m bursting to the rafters with spinning fodder… with no idea what I can move to bring my loom indoors. Hmmmm — your idea of putting the loom on the roof…

As to the cord you used for the tie-ups, is there a specific size I need to find? Do you have approximate YPP (yards per pound)? I’m pretty close to the Weaving Works, so will try to find it there first.

And what wire did you use for the replacement?

Thank You!

June 28, 2008 at 8:20 am

I am very interested to read about your experience of using the Bergman loom. I also have a compact countermarche loom, mine is a Toika Norjaana, and had reached very much the same conclusions. I love my loom, but if I had more space I’d go for a countermarche loom that was larger in all dimensions, one of the big Toikas or a Glimakra.

This is the first time I’ve looked at your blog, I found my way here via Peg’s “Talking About Weaving”, but shall certainly be back, I’m really pleased to find someone talking about countermarches.

July 14, 2008 at 11:30 am

Having only recently found you all I am finding all your experiences so helpful. I have had my great great aunts Bergman stuffed in a dusty corner for 30 years. decided to give it away to make space. Whilst finding out about these looms mainly from your discussions prior to giving it away I realised I wanted to try to bring it back to life.I trained as an occupational therapist in early 60s in Oxford UK and we learnt to weave. We had to weave a length of tweed on a 4-shaft foot power loom. In all my years working in mental health in NHS I have never ever woven but now I have retired I really want to. My Bergman is small.32″ wide. It has no back beam so I want to find out how to replace it, and the jack box was in 4 pieces. I am trying to find suitable cord at the moment to experiment with setting it up. Also the pins that go through the jacks are missing….but knitting needles do indeed fit.If anyone can give me any information, assistance, encouragement I would be delighted. I’m not sure that anyone in UK has one. i may be wrong…Deborah

August 3, 2008 at 6:36 pm

[…] been able to achieve this military precision with Texsolv, as I described earlier in the Texsolv post. Maybe that’s why Athena hasn’t yet blessed me with perfect sheds. I think the idea […]

August 16, 2008 at 10:14 am

[…] cord update: I looked into the smaller size of Texsolv tie-up cord Susan told me about after the Texsolv post, but according to the nice people at Woolhouse tools, the smaller cord is a really, really small […]

August 28, 2008 at 7:48 pm

I’m a long-time Glimakra CM owner (x2). My first came with linen loom cord (way before Texsolv). Believe me, it’s not something you would want to spin. I still have a a few pieces left, and all the ends are wrapped in masking tape to keep them together, otherwise they would unravel mercilessly. It appears only marginally thinner than the Texsolv, but I have no way of accurately measuring, perhaps 1 mm thinner. I haven’t read all of your blog archives, so I’m unclear about what is the real problem with the shed. But if you really want linen loom cord, then Joanne Hall at Glimakra USA or Becky at Vavstuga can probably get it for you. Joanne is also helpful with all kinds of CM loom problems, not just Glimakra. She has posted answers to CM problems on some of the various Yahoo weaving lists. Love your blog – just got here via Peg in NC.

September 24, 2008 at 9:56 pm

I’m a jewelry designer b trade and own the 59″ Toika Eeva counterarche loom. Thankyou for you blog info, it is quite helpful. I have another questiion. Climinb under the loom to do the tie ups is getting more and more difficult. I am considering computerizing. Do any of you have any opinions and thoughts on this?

I’ve been at AVL taking a course this week. And we were taught how to tie up a sectional warp. It was truly facinating, wonderful and exciting. Now, I need to get a secitional warping beam for the Toika. What a wonderful tight warp you get with the sectiional warping method. I also learned about the computer weaving programs and that was great too. Oh, I almost forgot… I was having trouble with my selvages drawing in and a fried of mine suggested using a shuttle with a pirn and tension. I used those this week also and WOW it really works.

Jennifer

September 25, 2008 at 9:08 am

Thanks for stopping by, Jennifer. I haven’t considered a computerized loom, but I can refer you to some bloggers who have gone that route. Tying up is the fly in the ointment, isn’t it?

If I ever buy another loom I’d like it to have a sectional warp beam. Two steps in one: sounds grand!

July 13, 2017 at 6:20 am

Wow, I just found you-ten years later. I was given a Bergman several years ago — loom, bench and a large box of string heddles. I wrote to the public library in Poulsbo seeking any information they might be able to give me. I received a lovely letter from Mrs. Bergman’s son in spidery longhand telling me of the history of the company and recalling working alongside his mother making looms in the 30’s and 40’s. A few weeks later, he wrote again. He’d gone to the basement and dug out some of the mimeographed instructions they included with the looms. Sadly, for me, none of the info was relevant to the model I have, but I do treasure the letters and provenance. I am willing to send copies of the letters to anyone interested.

January 8, 2022 at 4:21 pm

For anyone looking for linen loom cord in the US, it can sometimes be found at WEBS (yarn.com). If it is out of stock, they may be able to special order it for you. They are a Toika dealer and I believe they get the cord from Toika. If you are in Europe, then you can order it directly from Toika.