Mata Ortiz Runner

May 28, 2013

If you are wondering what my hand-turned maple bowl is doing in this photo, the answer is that it is pretending to be a Mata Ortiz pot. Mata Ortiz is a Mezzo-American revival pottery featuring clean forms and ornate surface decoration. I wove this runner for a couple of Mata Ortiz fans. (The bowl is also there because I’m just that awfully proud of having found it at Goodwill for $4 brand new. It’s the perfect shape to hold a ball of yarn, or for stuffing cut ends of thread into while weaving, and I’ve been using it constantly.)

Design constraints included the palette of the pots, the muddying effect of my putty brown sample warp, the narrow weaving width, the colors of cottolin I had on hand, and the fact that I ran out of one color mid-weaving!

Still, I found it really engrossing to design something so far outside the scope of what I’d design to please myself–to the point that I actually grew rather fond of it in the weaving. Now my only beef are the proportions. The central ochre section was longer in my sketches. I ran out of that color four inches early; it shows.

Runner: Mata Ortiz

Completed: March 2012

Woven on Varpapuu Kothe Nordia table loom

Threading: 8-shaft rosepath, 17 repeats plus balancer and selvedges.

Pattern: Interleaved zig-zag twill from handweaving.net (draft #12247, reverse side up for slight weft dominance), with overshot motifs in borders adapted from handweaving.net #12408, and basket weave hems (or rather the closest you can get to basket weave in rosepath).

Warp: sample warp in putty brown 8/2 unmercerized cotton mill ends, and border stripes of “Polo” (the color of unbleached linen) 8/2 unmercerized cotton by Uki

Weft: 22/2 cottolin (Borgs and Bockens: ochre, orangey red, turtle green; Louet: pastel green), white 8/2 cottolin from Pacific Wool and Fiber, 3/2 mercerized cotton in cornsilk yellow, and Lily size 20 perle cotton in light bronze (as tabby weft for overshot border motifs).

Warp preparation: wound 12 yards and 5” by the single thread on warping reel with cross at both ends, cut in half for 6 yard and 2 1/2” warp, beamed 8 epi in 2.5 dpi raddle

Ends: 275 total including floating selvedges, 95 dark, 80 light

Sett: 22.5 (ended up being more like 22.75) epi, sleyed 2-2-2-3 in 10 dent reed

Picks per inch: 23-26

Width in reed: 12”

Woven width: 11 3/8”

Finished width: 10 3/8” – 10 1/4”

Length on loom: 53 3/4″

Woven length: 52”

Finished length before hemming: about 48”

Hemmed dimensions: 42 5/8”

Loom waste: 13.5” back, but next time stop at 15”

Finishing: normal warm wash and tumble dry twice, remove from dryer while still slightly damp both times, hot iron, 3/4” slip-stitched hems.

Conclusions: Close sett reduced draw-in, though it muted the weft colors a bit more than I wanted. My beat was lighter for the first decorative border than the second, should have done more counting of ppi. The overshot figures in the second border looked squashed after wet finishing. Modified basket weave worked well for hems, but they are too thick. Next time bind raw edge with seam binding and fold only once to hem?

Locker Hooking with Sugar ‘n Cream Cotton Yarn

May 24, 2013

Wow, here’s is an old one. I finished it nearly a year ago. Even the photos are old. I snapped them before I stuffed it into a Christmas box along with the packing paper on a whim.

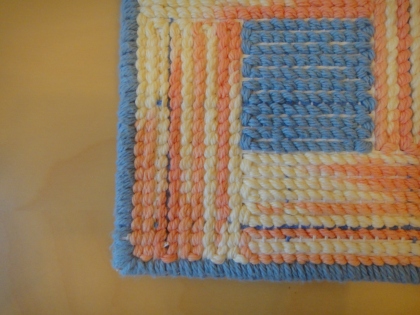

For the sake of completeness in documenting my locker hooking experiments, yes, it’s another trivet:

Measurements are 6.25″ by 6.25″. An inch bigger would have been better. It’s worked with two strands of vintage Lily Sugar ‘n Cream yarn on 5 mesh locker-hook canvas. I think I used a slightly fatter cotton for the locking yarn. Maybe the same blue I used as for the center square and to bind the edges?

Two strands of Sugar ‘n Cream gave good coverage, a single strand was not enough. I cut the strands off the ball strategically so I could keep the ombre color-changes matched up side-by-side. It was a bit of a pain catching both strands in the hook at once, but not too bad. They do want to twist around each other. Next time I would just let them. A person could make a very nice looped-pile bath rug or chair mats if their wrists were sturdy and they took it slow. Cheap yarn in lots of colors = plenty of patterning options.

Something I noticed: this older Sugar ‘n Cream, from my Great Granny’s knitting stash circa 1980’s, is nicer than the Sugar ‘n Cream yarn you can buy now. It’s rounder, more evenly spun, less pill-y, and I’m pretty sure just a higher grade of cotton. If I were to do a bigger locker-hook project with this yarn, I would be careful not to mix old skeins with new. The resulting pile would sport noticeable variations in and texture and in height.

First Warp on the Varpapuu Table Loom

February 27, 2013

My first warp on the Varpapuu table loom needed to be low-risk, since I had no clue how well the loom would weave, or whether the very small rust spots on the reed would transmit stain. Nothing too light or precious.

Back to the putty-brown 8/2 cotton mill ends then, with some unbleached-linen-colored stripes by the edges to keep it from boring me! I warped up about 6 yards and threaded for 8-shaft rosepath, 12 inches wide in the reed. So far I have woven off (and cut off, and wet finished) a bunch of samples, mostly in the form of napkins. This was the first time I used the double stick header described by Peggy Osterkamp to reattach a warp-in-progress to the cloth beam. I was nervous I would do something dumb like cut in the wrong place, but it worked out fine.

For the second half of the warp I wove some more samples, then started this little runner based on the information I’d gathered from my wet-finished rosepath twills. It’s a gift for a couple who loves Mata Ortiz pottery, and that’s all I really know about their taste; the general idea is to end up with something that will complement the vivid earth tones and set off the high-contrast geometric patterning of the pots.

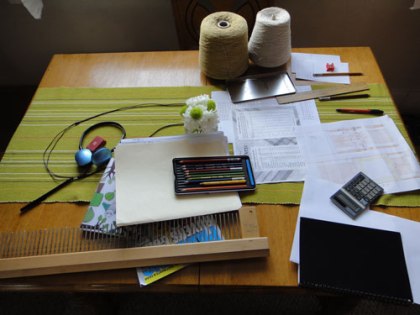

Numbers Just Confuse Me

February 23, 2013

Last month I quickly made myself comfortable with the Varpapuu table loom and worked out the easiest way to follow drafts. When I showed him my color-coded levers and notation system and explained, “numbers just confuse me,” Der Mann laughed out loud. He has seen me planning weaving projects, the pages and pages of scrap paper scribbled with numbers and diagrams that drift around the house; he’s heard me mumbling numbers as I wind my warps.

What can I say? There are numbers, and then there are numbers. Some you need, others just mess you up.

A Day in the Life of Looms, 2013

January 1, 2013

Once again, Meg hosts a New Year’s peek at a bunch of people’s looms!

Here are my contributions.

Heddles:

I counted, bundled and washed these loom-components yesterday because they stank the with stink of the former owner’s sprayable de-stinkifier. I don’t really believe in washing heddles, but let me tell you, I had no choice. They are drying on the sewing machine table out of the reach of the cat.

Above center: Varpapuu Kothe Nordia 8-shaft table loom with cracked floor stand, circa 1970’s, 31.5 inch weaving width . . .

. . . which is still recovering from it’s de-stinkifying ordeal by soap and water. Those cute Finnish shuttles on the sewing machine table came with the loom as well. Also the plastic bed-lifters. Ah, craigslist! I bought it the day before yesterday, now all that’s left to do is to put the shafts back together and string ‘er up.

Above right: Bergman 8-shaft countermarche.

Also known as the moveable hat shelf, as you will notice it has moved from one side of the room to the other since last January. 2012 was a year of pain and illness. My back is not improving. I can’t treadle this loom unless it does.

Standing inkle and Pysslingen 4-shaft table looms:

The standing inkle loom has another 20/1 linen band on it. I made three others in 2012, maybe I will blog about them some time.

The Glimåkra table loom of last year is still incomplete. It turned out to be surprisingly hard to find the right size of lumber for Pysslingen heddle bars, for so many reasons. After a failure with warpy oak I scrounged the last straight pieces of some clear Douglas fir at a restoration millwork place and made the bars. That is where I stalled out: my next step is making a jig to accomplish the precision drilling to add the hardware to the bars, and you know what? I don’t really like to fix looms. I’m tired of it. I would rather weave. That is why I decided to get the Varpapuu. Plus, the price was right. Plus, it has eight shafts instead of four. And it’s wider. And deeper. I do still plan on finishing making the Glimåkra heddle bars, just not right away.

Today I de-rusted my warping reel and planned my first warp for the Varpapuu. Tomorrow I will wind it and beam it.

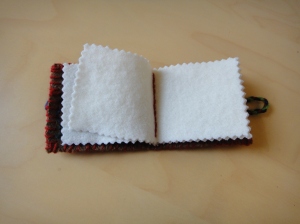

First Crewel Project: Sheep and Blueberries

December 21, 2012

Here is the woolen needle book I finished earlier this month for a gift.

The cover is a strip of a heavy brushed merino twill measuring 5 7/8” x 2 5/8”. The “pages” are two pieces of wool flannel with pinked edges cut to about 5 1/4” x 2 3/8”. The book measures 2 7/8” x 2 5/8” closed. For the clasp I made a loop and Chinese button knot from a couple of four-strand kumihimo braids.

Kyuuto! Japanese Crafts: Woolly Embroidery published in English by Chronicle Books is what inspired me to try making a needle book. The sheep, a repeated motif in the book, is stitched from angora yarn in a detached buttonhole stitch.

This is my first finished crewel project, if you don’t count the sampler I made when I was 12. It’s a smaller than I would have liked for utility. My next needle book (if there is one) will be at least 3.5″ x 3″. Here I was limited by the narrow width of my twill scraps: they were the strips I’d removed from the ends of an old piece of yardage to square it up on the grain so I could make it into a cat blanket. My grandmother bought the material ages ago to make a structured wrap, but the moths got to it in a couple of places so she gave it to me.

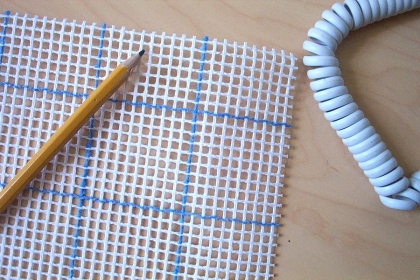

Locker Hooking with Poppana

June 26, 2012

After rya yarn, I decided to try locker hooking with Finnish poppana. I love this stuff and am still trying to figure out the best use for it. Poppana is a continuous strip of colorfast cotton bias tape wound onto a spool, and so has the pleasing property of developing a furry edge rather than raveling in the wash.

I graphed a pattern for a trivet (6” x 8 1/8” when finished) with eight sides (corners are less acute this way, and easier to cover when whip-stitching the turned edges), hooked it, washed it, dried it.

Here’s the back:

Poppana gets softer the more you wash it, but I wanted this to be soft right away; I pulled it through a steel knitting-needle gauge as I worked to distress the edges and rubbed them when I gave it a hot hand wash followed by a tumble dry. The locking yarn is the same dark beige Finnish “Linnea Novita” 4 ply 60% linen, 40% cotton I used for the last trivet, about 13 wraps per inch.

Poppana folds over on itself when pulled through the 5 mesh canvas but still seems to cover the locking yarn pretty well. I’d locker hook again with poppana, especially if I can find a soft, open linen canvas with 6 or 7 squares to the inch and a skinnier locker hook.

Locker Hooking with Vintage Rya Yarn

June 20, 2012

So, I’m not up for much. But early this spring I bought some real locker-hook canvas–as opposed to my allergenic home-made version–because I had some large projects in mind. It is a stiff 50% cotton, 50% polyester blend leno, heavily starched to keep the mesh from shifting.

I chose the 5 mesh version (five holes to the inch) because it was the smallest I could find. I have no interest in working with rags, and I can’t imagine using anything but wide rags with the more common 3.75 mesh canvas. Even then the work would come out sparse and coarse.

My first project was a sample trivet. I have two hulking rolls of late 1960’s / early 1970’s “Sellgren Ryer” yarn that came to me with my loom: beautifully spun Norwegian wool from same town as my favorite cathedral. My sample was to tell me a) if I liked the two colorways together b) if the yarn made a goodly-packed pile when worked through the 5 mesh canvas, and c) how quickly does locker-hooking use it up. Do I actually have enough of this stuff for a rug?

All this I learned and more beside. The rya yarn actually is a bundle of different grists and coordinating colors of yarns wound side-by-side. When you’re fishing to hook a loop by feel on the underside of the canvas, it’s really hard to grab all the yarns at once. Individual strands keep slipping free from the bundle, especially the the lace-weight ones. I often had to undo my work to retreive them.

The other problem was one I didn’t expect. As far as I know there is only one U.S. maker of locker hooks (crochet hook with a needle eye at the end of the handle) and they only come in one size. Mine is aluminum, and what do you know? It is TOO BIG to pull smoothly through the unforgivingly starch-stabilized 5 mesh canvas, especially when pulling a fat load of yarn. Struggle, struggle, struggle all the way! Maybe the steel locker hooks from England are a little skinnier? I hope so.

All in all it was a most uncooperative trivet. I chastised it sternly and swore never to touch locker hook to rya yarn again.

Though it did turn out wonderfully dense and spongy:

And no, I do not like the color combination. It’s not horrible, but after a while I realized that putting these two yarns together manages to make the least of each colorway. The subtle loden looks drab and the blue looks harsh. Separately they are lovely. If I use them (and it won’t be for anything locker hooked!), I’ll pair them with solids to play them up. Those old large, multi-stranded, un-cut skeins of Paternayan would be about the best match for texture. At the moment however I have no immediate rugmaking plans and refuse to trawl eBay or Etsy for antique yarn. That way madness lies.

Oh how I hate to take pictures. These napkins have been done for ages now. Well, they’ve been done for more than a month, which is a lot less than the eternity I spent weaving them.

Eternity Napkins

Completed February 2, 2012, woven on Spear’s rigid heddle loom.

Pattern: Erika de Ruiter’s “Magic-Step” shaded color-and-weave-effect basket-weave blocks from May 2008 WeaveZine. I threaded seven blocks (37 tr each) plus balancer (1 tr) plus altered borders (20 tr each) and wove seven blocks for each of two napkins, plus some extra cloth in plain warp stripes.

Warp and Weft: mixture of Spectrum golden willow-bud green and Uki unbleached white 8/2 unmercerized cottons.

Warp Length: 2 yards and a couple of inches.

Ends: 300 plus 2 weighted floating selvedges.

Sett: single-, double-, and triple-sleyed in 9.25 epi heddle for a little more than 17.5 total epi.

ppi: about 16

Width in reed: 17 1/8”

Weaving width: 15 1/2”

Width off loom 15 3/4-16”

Finished width: 14 1/4”

Length on loom: forgot to tally

Length off loom: 57” total, 20” each napkin including 1 3/4” hem allowances, 17” extra cloth.

Finished length: 51 1/2”

Loom waste: 9” rear, 4” front

Finishing: Hot hand wash with long soak, hot machine wash and tumble dry, hot iron, hand hemmed.

Finished dimensions: each hemmed napkin is about 14.25” wide by 15.5” long.

Conclusions:

Unless you are a glutton for punishment there’s no good reason to weave this pattern on a rigid heddle loom. Using two shuttles and weaving at 16+ picks per inch is bad enough, but the main problem is the need for floating selvedges. On a rigid heddle loom, selvedges can’t float. The best you can do is thread them in the slots of your heddle (not the holes) so they have a little freedom of movement, then you must remember to twine your shuttle over or under them at the start and finish of each pass regardless of whether your selvedge threads happen to be on the top or bottom of the shed. Doing this on top of trying to keep track of whether you must weave one, two, or three picks of each color in the same shed–a constantly changing series within each pattern block–makes a lot to keep in mind. Also worth noting is the constant stress on the selvedge threads. The twining stretches them out, which makes it necessary to suspend them over the back of the loom with weights rather than beam them with the rest of the warp.

I made a lot of mistakes that had to be fixed off the loom. With basket weave it’s really hard to see when you catch a stray warp thread, and the low tension of rigid heddle weaving makes it really easy to do.

At 17.5 epi these napkins tracked and and were a more open weave than I’d hoped. The sett should certainly have been closer–maybe 20 epi for 8/2 cotton–but I think there would be an inclination to track no matter how close the warp, because that is how the variable basket-weave wants to behave. I noticed that the towels in the WeaveZine photo looked like they’d had the bejeezus ironed out of them–maybe that’s why. Neither of these particular cotton yarns shrank or fulled as much as I’d hoped, but somehow the off-white Uki 8/2 was slightly harder and thinner than than the 8/2 Spectrum even though it was not as heavily twisted, and the Spectrum fluffed up and dominated it a bit after the napkins were washed. Cottolin might be a better option for a crisp rendition of the pattern, which has a lot of interesting possibilities.

A Day in the Life of Looms, 2012

January 1, 2012

I was wondering why taking a few en deshabille photos of my looms and looking at other people’s looms in the same condition turned out to be such a refreshing exercise last year. Here’s what I think. It’s hard to get a clear look at something you walk around daily, dust around weekly (Ha! Fat chance!), and the very nature of which is to be a means to an end. When I look at my looms I see cloth or lack of it. Easier not to look. But you can’t not see something when you stick it in a rectangle, click the shutter, and pass it around for others to see too. Somehow it just feels right to look at things squarely on the first day of the year. A great idea, Meg.

Bergman 8-shaft countermarche: The ironing hanging on it pretty much tells the story. My Bergman has not had a warp since we moved to into this house nearly three years ago. My hips may allow me to weave on it again someday, they may not. C’est la vie! (Sorry, feeling French today, I have been watching surrealist cartoons.) The wooden pieces on the bench are components of a band loom I mean to make.

Spears rigid heddle: Here is the end of a warp for 3 large napkins in an adaptation of Erika de Ruiter’s “Magic-Step Towels”–only the final border and a little extra are left to weave off. I was intrigued by the idea that such a complex-looking pattern could be woven on a rigid heddle loom. Word to the wise: just because you can weave something on a rigid heddle loom doesn’t mean you should. This was the slowest weaving I’ve done. Ever. Eternity napkins. I should bronze them.

Standing inkle: 20/1 linen band. I would like to weave a bunch of these in different colors and designs. I have a plan for using them together, and a lot of this vintage linen thread.

8-shaft table loom: Fooled you! The homemade 8-shaft table loom is GONE. What you see below is a different loom entirely. A few months ago I sold the old 8-shaft in just the way I had hoped–remodeled into good working order, for much less money than I paid for it, with a clear conscience, to a deserving new weaver!

Pysslingen 4-shaft table loom: I had decided that if I ever bought another table loom, it would have to be an older Glimåkra because no other kind was worth the trouble. I did not really think I would find one. Then I did. This loom has never been warped or even fully assembled. It is essentially a brand new 35-year-old loom . . . without heddle sticks. The original owner stashed them somewhere years ago and wasn’t able to find them when she put the loom up for sale. Pre-milled lumber doesn’t come in the right size for replacements, and Glimåkra no longer stocks parts for this loom (its successor the Victoria has metal shaft bars), so at the moment I am in heddle stick limbo. I might get an email telling me that the former owner has found them in her basement the same way she found the reed and cords and heddles a week after I bought her loom, or I might just get help from someone with a table saw.

Happy winding, warping, and weaving in 2012!